05

The beginning of the current Shinohara Shiko

Participating in a big project like never before

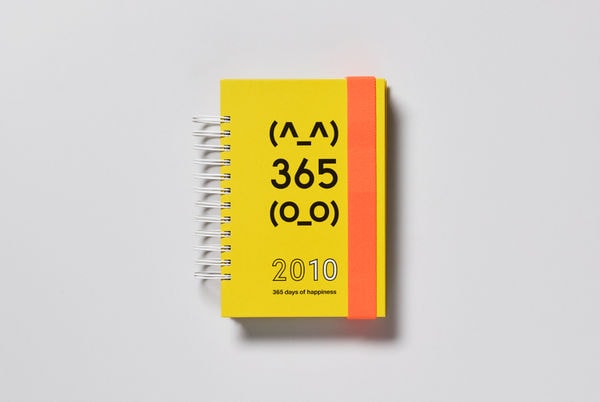

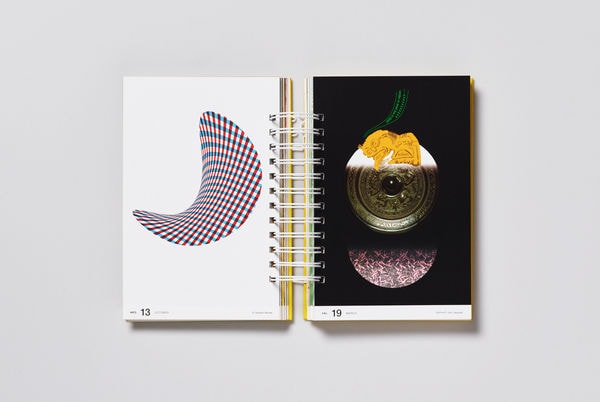

A page-a-day calendar issued through a project between Heidelberg Japan Co., Ltd. and the Japan Graphic Designers Association (JAGDA) in 2010. Not a single page uses the same technology or paper, and each day is designed by 365 different designers.

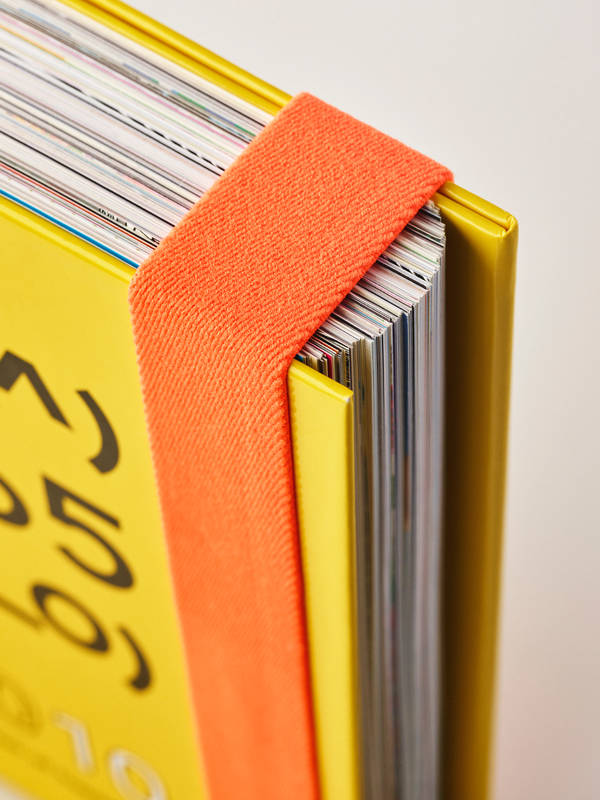

Unlike normal page-a-day calendars, it uses 365 thick sheets of paper, making it a solid calendar. When the binding method of this calendar was being considered, it was decided that Shinohara Shiko would become involved after receiving consultation from Mr. Heidel. Considering the outline of the project and the specifications of the calendar, Shinohara thought it would be best to use a two-ring binder. He created a simple two-ring binder sample and attended the meeting. However, there was a request from the art director of this project to bind the calendar using a double ring. “A removable 2-ring binder should not be used because if you take out the pages, it would be difficult to put it back.” The idea was rejected with these words.

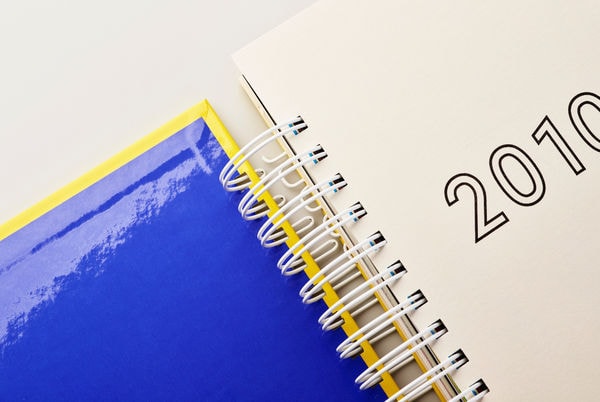

Since there were no double rings that could bind the thickness of this calendar, they contacted spring manufacturers and others to negotiate a custom-made product, but it was abandoned due to it not meeting the budget.

Upon consulting an affiliated company that they usually work with, they found out that there are large double rings in the UK. However, even if the rings are imported, there are no machines to bind it…What to do? Then they decided to create that machine, resulting in the manual (50mm) ring binding machine. (Making a machine is this easy…)

Surprise and inspiration for the world of designers

Shinohara participated in the meeting again with the confidence that “he could do it”, and was imagining a desk calendar in the horizontal position. However, the art directors and designers proposed a specification for a calendar in the vertical position where the unstable portion would be fixed with a thick rubber band.

From a bookbinding standpoint, he secretly thought “What…that’s difficult to use….” Shinohara says that at that time, the designers all seemed incomprehensible to him.

The things that surprised him at the meetings were not limited to bookbinding. At the meetings about the main text of the calendar, he would exchange greetings with many designers for the first time, and there would be people participating in the meetings with casual clothes wearing a hat, stylish senior designers who were much older than him, and many people who were different from the people that were usually around him. He still remembers being inspired by such people.

Turning other people’s anger into motivation

The meetings for the main text were not easy either. The director’s request was to make it random so that no single page would use the same paper or printing technique. However, in the world of bookbinding, this randomness can cause out of order and missing pages, so Shinohara wanted to somehow avoid it.

When Mr. Heidel and Shinohara Shiko decided on some rules between only them, this caught the attention of the director, and he reprimanded them. This was the first time Shinohara had been reprimanded as an adult. He decided to start from scratch, thinking of a new method to integrate randomness and work efficiency by changing his frustration to motivation.

He would work on the specifications until late at night with the affiliated company, and they managed to create a method that prevented out of order and missing pages and finally reached the stage of actual production.

Sleepless night with pressure like never before

There were a total of 6 printing companies and 365 designers involved. Adjustments such as color proofing were needed to be carried out with about 60 designers per printing company. At that time, Shinohara had no knowledge of printing, so he could only watch the difficulties of the printing companies on the side. However, because he had come to know about these difficulties, when he thought about the unbound books that would arrive at his bookbinding factory all at once from all over Japan and how he would have to do the cutting process, he felt an immeasurable amount of pressure.

The cutting process cannot be undone once a mistake is made. He could not sleep the night before the binding process when he considered the efforts of the printing companies and designers up to this point. He also gave detailed instructions and made sure to do repeated checks on-site for the production.

In the end, the product was delivered without any major issues, and at a later date, the director who was angry at Shinohara said, “You did well. Only you could have done this job.” All of the anxiety and hardships were blown away at once, and he was filled with joy.

The director’s anger at that time must have also been a result of his overflowing energy toward the work, and the determination to go on equal footing against that led to a good relationship.

Looking back, this led to the current Shinohara Shiko

At that time, Shinohara Shiko was mostly responsible for supplying unbound books for printing companies, and had almost no involvement in productions from the early stages or direct work with designers. It was just a matter of quickly doing the work that was given. However, in this project, each step was important, and it made us realize the joy of being aware of and being involved in each step. It gave us a chance to start the bookbinding business from a new perspective.

It was around this time that we started to think about the meaning of design, imagine the intent of the designer, and create as a team with a shared direction. This project was what created the origin of Shinohara Shiko, and it was the most difficult project to date.

When I say “difficult project”, you may think of the technical aspect, but the most difficult aspect is not technology, but rather how you interact with people. However, the more difficult it is to interact with the person, the more emotions they will make you feel, and the stories that result from that is one of the joys of doing this job.

担当 : 篠原慶丞

今でも記憶に残る、篠原紙工にとっても私にとっても大事なプロジェクトです。